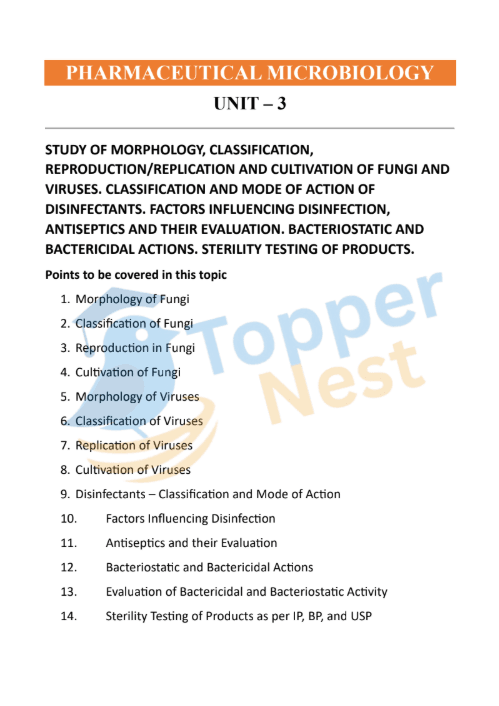

In hospitals, research laboratories, and pharmaceutical factories, an invisible battle is constantly underway. Fungi, viruses, and bacteria threaten product safety and human health, while disinfectants and sterility testing work as powerful defenses. UNIT 3 explores this crucial intersection of microbial biology and infection control, helping students understand how microorganisms grow and how science keeps them in check.

From antifungal drugs to sterile injections, microbiological control ensures medicines are both effective and safe.

Fungi: Morphology, Classification, and Growth

Morphology of Fungi

Fungi are eukaryotic microorganisms with a defined nucleus and complex cellular structure. Their bodies typically consist of:

- Cell wall made of chitin

- Filamentous hyphae

- Mycelium network

- Spores for reproduction

These structural features make fungi more complex than bacteria.

Classification of Fungi

Fungi are grouped into:

- Yeasts (unicellular, oval-shaped)

- Molds (multicellular, filamentous)

- Dimorphic fungi (exist in both forms)

Each type has medical and industrial importance, ranging from infections to antibiotic production.

Reproduction and Cultivation

Fungi reproduce through budding, fragmentation, or spore formation. They are cultivated on media like Sabouraud dextrose agar under slightly acidic conditions.

Proper temperature, moisture, and oxygen supply are essential for successful growth in laboratories.

Viruses: Structure, Classification, and Replication

Morphology of Viruses

Viruses are acellular particles composed of:

- Genetic material (DNA or RNA)

- Protein capsid

- Sometimes a lipid envelope

They lack independent metabolism and depend entirely on host cells.

Classification

Viruses are classified based on:

- Type of nucleic acid

- Capsid symmetry

- Host specificity

Replication and Cultivation

Viruses replicate only inside living cells. Cultivation methods include:

- Tissue culture

- Embryonated eggs

- Laboratory animals

These methods allow study of viral diseases and vaccine development.

Disinfectants and Antiseptics: Chemical Weapons Against Microbes

Classification of Disinfectants

Disinfectants are chemical agents used to destroy microorganisms on non-living surfaces, while antiseptics are used on living tissues.

Common classes include:

- Alcohols

- Phenols

- Halogens

- Aldehydes

- Oxidizing agents

- Quaternary ammonium compounds

Mode of Action

They work by:

- Protein denaturation

- Membrane damage

- Enzyme inhibition

- Oxidation of cellular components

Selecting the correct disinfectant depends on the organism and environment.

Factors Influencing Disinfection

The effectiveness of disinfectants is influenced by:

- Concentration of agent

- Contact time

- Temperature

- pH

- Presence of organic matter

- Microbial load

Failure to control these factors reduces efficiency and may lead to contamination.

Bacteriostatic and Bactericidal Actions

Understanding the Difference

- Bacteriostatic agents inhibit bacterial growth

- Bactericidal agents kill bacteria completely

Evaluation Methods

Common tests include:

- Minimum inhibitory concentration (MIC)

- Minimum bactericidal concentration (MBC)

- Phenol coefficient test

These evaluations determine antimicrobial potency and clinical suitability.

Sterility Testing of Pharmaceutical Products

Sterility testing ensures pharmaceutical products are free from viable microorganisms before patient use.

Types of Products Tested

- Injectable liquids

- Powders and solids

- Ophthalmic preparations

- Implants and sterile devices

Testing Methods

- Membrane filtration method

- Direct inoculation method

Both methods detect microbial contamination using growth media.

Official Pharmacopoeial Standards

Sterility testing procedures follow guidelines established by:

- Indian Pharmacopoeia (IP)

- British Pharmacopoeia (BP)

- United States Pharmacopeia (USP)

These standards maintain consistency, quality, and patient safety worldwide.

Why Sterility Matters in Healthcare

Contaminated medicines can cause serious infections and treatment failure. Therefore:

- Strict sterilization is mandatory

- Regular testing ensures safety

- Quality control protects patients

Sterility assurance remains a top priority in pharmaceutical manufacturing.