Before a medicine reaches a patient, it must flow, mix, compress, and spread correctly. Syrups must pour smoothly, creams must spread easily, and tablets must resist breaking during packaging. Behind all these behaviors lies one powerful science—rheology and the mechanics of solids.

UNIT 2 focuses on how liquids flow and how solids deform under stress. These principles guide pharmaceutical formulation, manufacturing, and quality control. In short, understanding flow and deformation helps ensure that medicines are effective, stable, and easy to use.

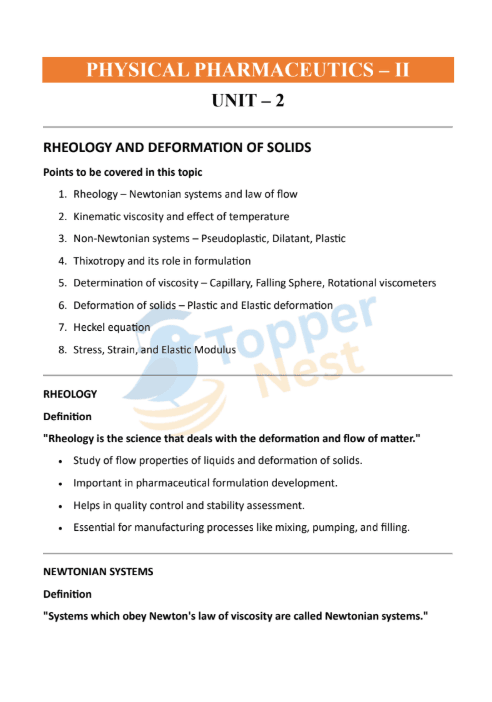

Rheology: The Science of Flow

What Is Rheology?

Rheology is the study of the flow and deformation of matter. It explains how liquids, semisolids, and suspensions behave under applied force.

In pharmaceuticals, rheology determines:

- Pourability of liquids

- Spreadability of creams

- Stability of suspensions

- Ease of processing

Newtonian Systems

Law of Flow

Newtonian liquids obey Newton’s law of flow:

Shear stress is directly proportional to shear rate.

This means viscosity remains constant regardless of applied force.

Examples

- Water

- Alcohol

- Dilute solutions

These systems show straight-line flow curves.

Kinematic Viscosity

Kinematic viscosity is defined as:

Viscosity ÷ density

It reflects how fast a liquid flows under gravity.

This parameter is especially useful in characterizing syrups and solutions.

Effect of Temperature

Temperature strongly influences viscosity.

- Higher temperature → lower viscosity

- Lower temperature → higher viscosity

For example, syrups flow faster when warmed.

Maintaining temperature control ensures consistent drug performance.

Non-Newtonian Systems

Unlike Newtonian fluids, non-Newtonian systems show variable viscosity.

Types of Non-Newtonian Flow

Pseudoplastic (Shear Thinning)

Viscosity decreases with increasing shear.

Examples

- Paints

- Creams

- Polymer solutions

These are easy to spread and ideal for topical formulations.

Dilatant (Shear Thickening)

Viscosity increases with shear.

Examples

- Concentrated suspensions

These systems resist sudden flow.

Plastic Flow

Requires yield stress before flowing.

Examples

- Toothpaste

- Ointments

This prevents leakage during storage.

Thixotropy

Thixotropy refers to time-dependent shear thinning.

When shaken or stirred, viscosity decreases and later recovers.

Thixotropy in Formulation

- Easy pouring

- Better stability

- Prevents sedimentation

- Improved patient convenience

Thixotropic systems are common in suspensions and gels.

Determination of Viscosity

Methods of Measurement

Capillary Viscometer

Measures time required for liquid to flow through a narrow tube.

Simple and suitable for Newtonian liquids.

Falling Sphere Viscometer

Determines viscosity based on the speed of a falling ball in liquid.

Useful for transparent liquids.

Rotational Viscometer

Measures resistance to rotating spindle.

Best for non-Newtonian systems and semisolids.

Widely used in pharmaceutical laboratories.

Deformation of Solids

While liquids flow, solids deform when force is applied. This is crucial in tablet manufacturing.

Elastic Deformation

Material returns to original shape after stress removal.

Important during tablet compression recovery.

Plastic Deformation

Permanent shape change occurs.

Essential for forming strong tablets.

Both behaviors influence tablet hardness and durability.

Stress and Strain

Stress

Force applied per unit area.

Strain

Resulting deformation.

These parameters help evaluate material strength and compressibility.

Elastic Modulus

The elastic modulus measures stiffness.

Higher modulus → harder material

Lower modulus → softer material

This helps choose excipients for tablet formulation.

Heckel Equation

The Heckel equation describes powder compaction behavior during compression.

Importance

- Predicts compressibility

- Evaluates plastic deformation

- Optimizes tablet formulation

- Ensures consistent tablet quality

It is widely used in pharmaceutical engineering.

Why Rheology and Solid Mechanics Matter in Pharmacy

These concepts directly influence:

- Syrup consistency

- Cream texture

- Suspension stability

- Tablet strength

- Manufacturing efficiency

Proper rheological control ensures better patient compliance and product stability.